01. Objectives

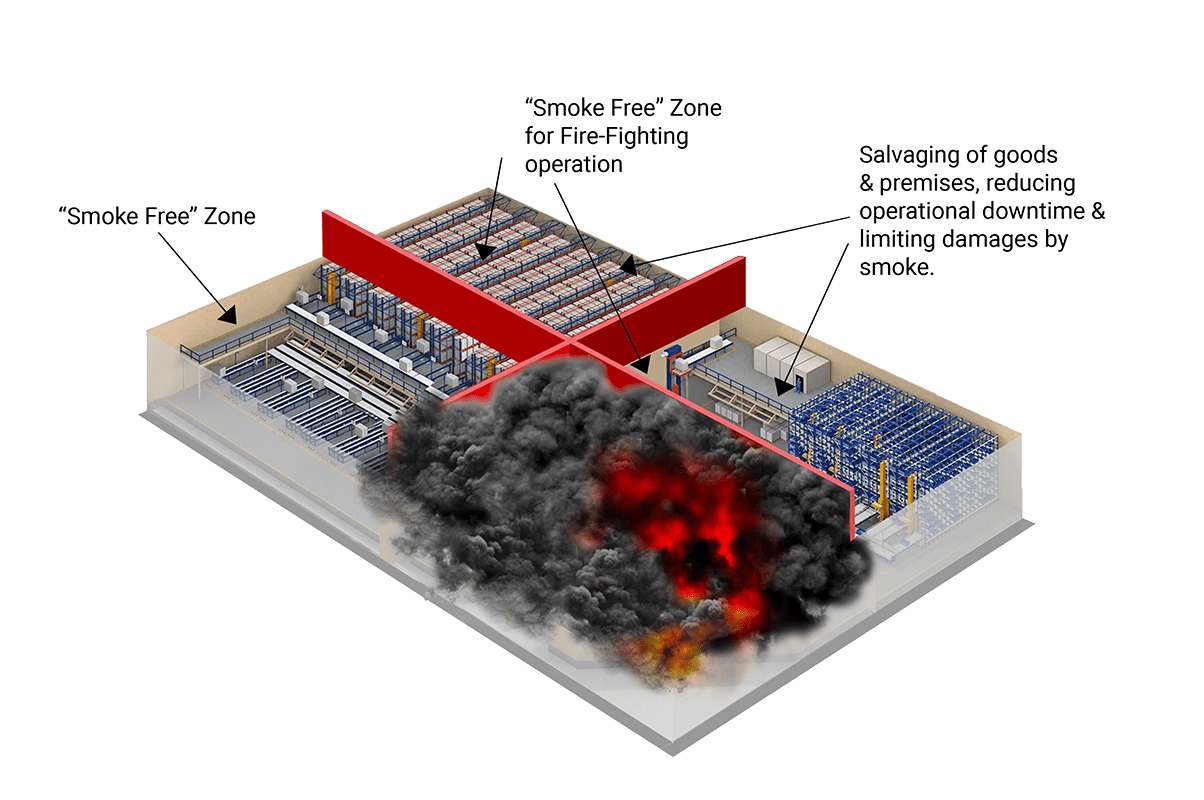

Generally, smoke control systems are used to improve life safety, aid firefighting or property protection. The system should be designed to be as simple and reliable as possible in line with the objectives of the smoke control system;

- To improve tenability and visibility for firefighting and evacuation.

- To limit smoke spread during phased evacuation.

- To limit damages to equipment and furnishings caused by smoke.

02. Tenability Limits

All safe escape routes should be protected from the effects of fire by passive measures such as fire compartmented corridors or stairs or active systems such as smoke control systems or a combination of both. Tenable conditions can be defined in terms of visibility and heat.

In terms of visibility limits, the escape routes should maintain a smoke clear layer above eye level of at least 2.5m above floor level or ensure that a minimum visibility of 10m through any smoke is maintained for occupants to see the exits and evacuate without undue hindrance.

In terms of heat, the smoke layer temperature should not exceed 200 degrees Celsius which is equivalent to a radiant heat flux of 2.5 kW.m-2. Above such temperature, any escape below such hot smoke layer would be deemed untenable.

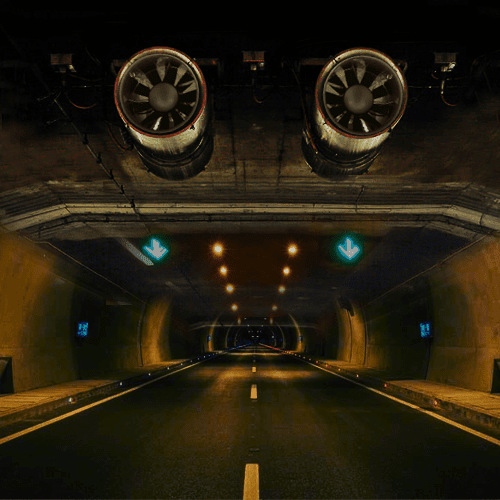

03. Types of Smoke Control System

Generally, there are 3 types of smoke control system;

- smoke extraction within the room of fire origin

- smoke extraction in the common corridor or circulation space

- smoke extraction within the atrium spaces

i. Smoke extraction within the room of fire origin

Independent smoke extraction system is required if the size of room exceeds 1,000m2 (natural system) or 1,300m2 (mechanical system).

ii. Smoke extraction in the common corridor or circulation space

Smoke is spilled from the room of fire origin into the circulation spaces for extraction. In this case, the common circulation space serves as a smoke reservoir for the ESCS or SHEVS.

iii. Smoke extraction within the atrium spaces

Smoke from the room of fire origin plumes into the atrium spaces for smoke extraction.

Channeling and containment smoke curtains are usually required to limit the smoke plume into the atrium as well as to prevent smoke spread into the upper floors.

04. Design Fire Sizes (Sprinklered)

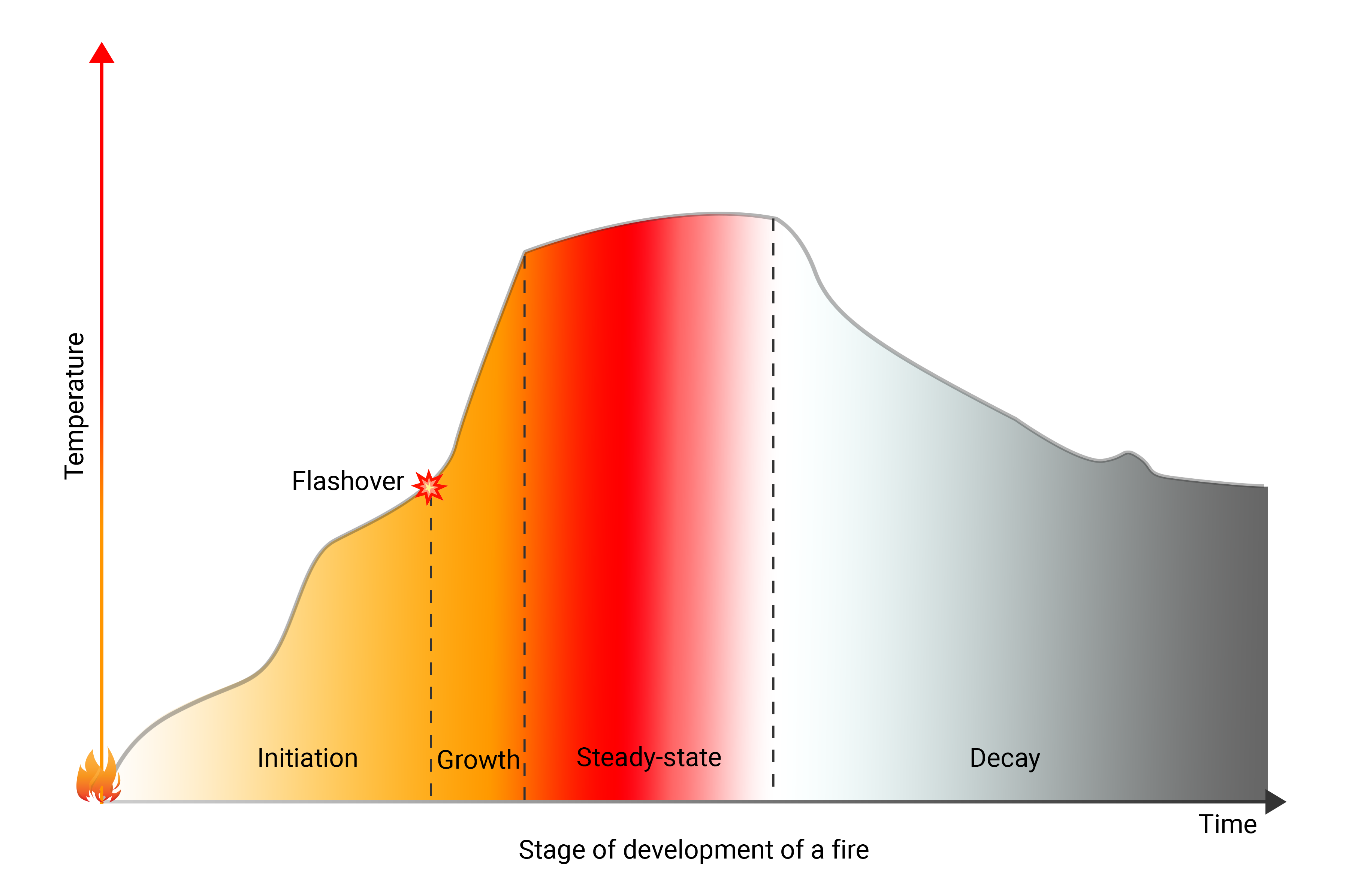

For design purposes, the design fire size may be categorised into:

- Growing fire

- Steady-state fire

It is commonly assumed that the fire stops growing when the sprinklers are activated. The design fire size is estimated to be the size the fire has grown to at the moment of sprinkler activation. For design purposes, the sprinkler activation time may be taken as the time for the activation of the 2nd ring of sprinklers.

05. Smoke Reservoirs

Based on experimental testing limited to the size of test rig, typically, an area of 2000 to 3000 m2 has been adopted as the maximum smoke reservoir size to prevent excessive cooling of the hot smoke layer and the downward mixing of the smoke with the clear layer below.

In fire safety engineering for larger enclosures, such cooling and downward mixing of smoke may not occur until the fire has decayed. Therefore, larger smoke reservoirs may be feasible subject to further analysis and assessment through CFD modelling.

06. Fire Compartmentation

A fire will progress through various stages from ignition to fully developed unless action is taken to suppress or extinguish it. Up to flashover condition, the rate of growth of a fire can be restricted by controlling flame spread, heat release and ease of ignition. However, once flashover has occurred, it is necessary to restrict the spread of fire by containment. Such containment of fire is known as compartmentation.

The ability of sprinklers to control fires means that the sprinklers have been used to justify the increase of the size of compartmentation and / or reducing the fire resistance requirements of the enclosing boundaries. Prescriptively, compartment sizes have been allowed to be doubled with the provision of sprinklers. However, for fire safety engineering solution, the effective relationship between compartmentation and sprinklers should be developed accordingly.

07. Effects of Sprinkler System

As the smoke plume rises from a fire, it entrains air from the surroundings which causes the smoke plume to cool. The higher the ceiling, the lower will be the temperature of the smoke which reaches the sprinklers. The hotter the smoke, the more rapidly the sprinkler will activate.

The time to sprinkler operation depends on :

- fire growth rate

- sprinkler location

- thermal sensitivity

Thermal sensitivity of a sprinkler determines how fast it will heat up once immersed in a hot gas layer such as the ceiling jet plume from a fire. The thermal sensitivity is characterised by its Response Time Index (RTI). A smaller RTI value indicates a more thermally sensitive element. The parameter used to describe sprinkler sensitivity is known as the response time index or RTI.

In general, the use of a fixed fire size is deemed as the conservative solution (usually adopted in prescriptive fire codes). The design fire sizes can be determined by the active fire protection system that is installed.

(1) If automatic sprinkler system is installed, fire size can be determined based on 2nd ring of sprinkler activation

(2) If alternative water suppression systems are installed in lieu of sprinklers, fire size can be determined based on the following:

- Pre-action sprinklers

- Deluge system

- Water monitor system

Widely used computer programs known as DETACT-T2 and FPETool are able to predict sprinkler response times and corresponding fire sizes at sprinkler operation by combining the effects of fire growth, sprinkler location and sprinkler sensitivity.

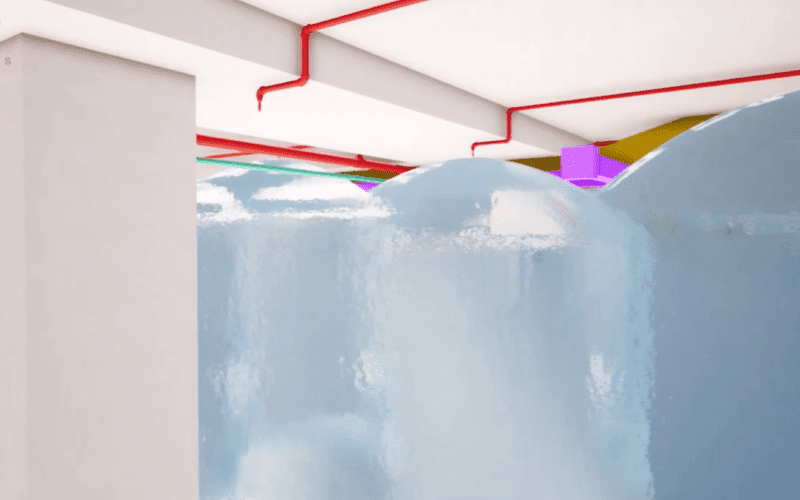

Simulation of the Sprinkler Umbrella Water Spray Pattern

The surrounding services may pose as obstructions to the umbrella water spray of the sprinklers thus reducing the sprinkler effectiveness.

Formal assessment based on the FM Global installation guidelines for sprinklers may be used to determine the effective fire sizes where necessary.

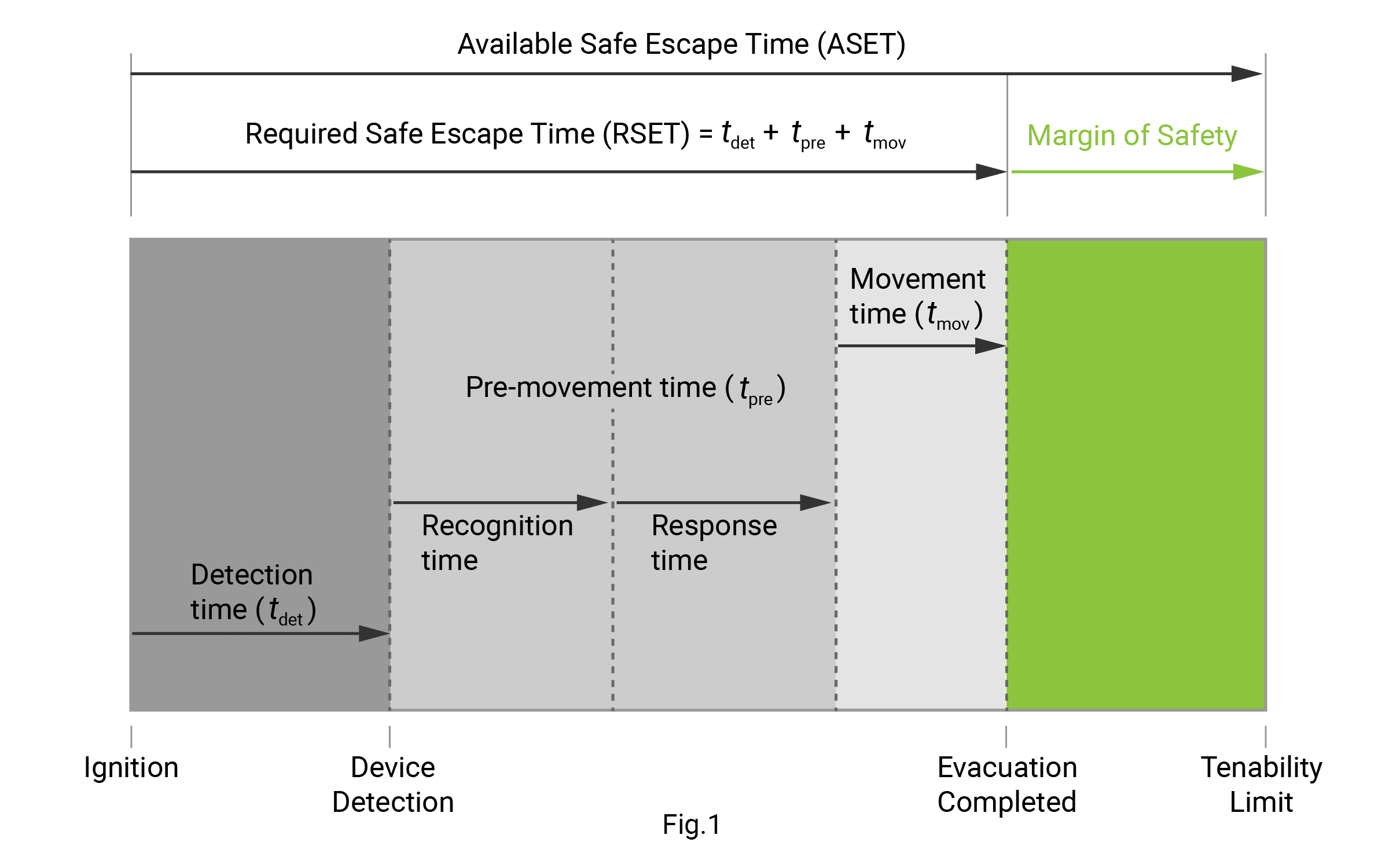

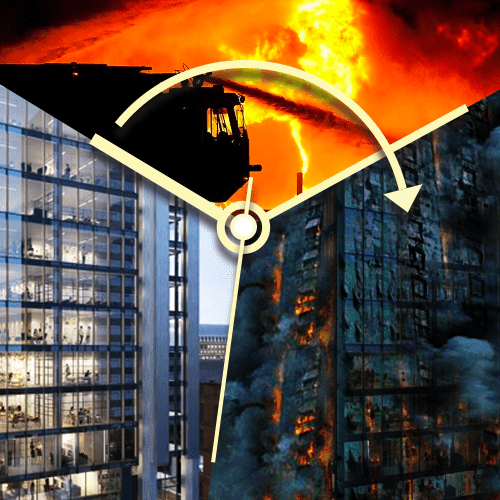

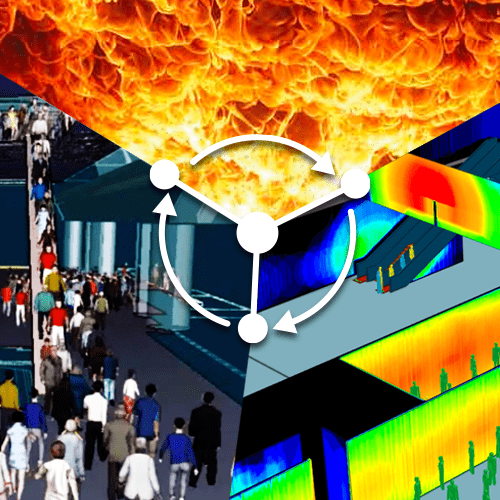

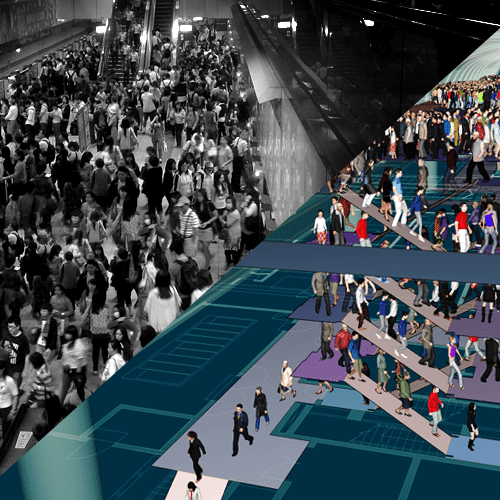

08. ASET > RSET

Prescriptive codes require minimum exit widths and maximum travel distances with no mention of the time required to escape. In fact, during a fire scenario, the escape process is very time-related. For any escape design to be successful, the time available for evacuation before untenable conditions occur must be greater than the minimum time required for escape. In other words, ASET > RSET

ASET : Available Safe Escape Time [the time from fire ignition to start of untenable conditions]

RSET : Required Safe Escape Time [the time upon fire ignition till complete evacuation of the occupants to a place of safety]

The general methodology to estimate the total required safe escape time (RSET) is illustrated in Fig.1.

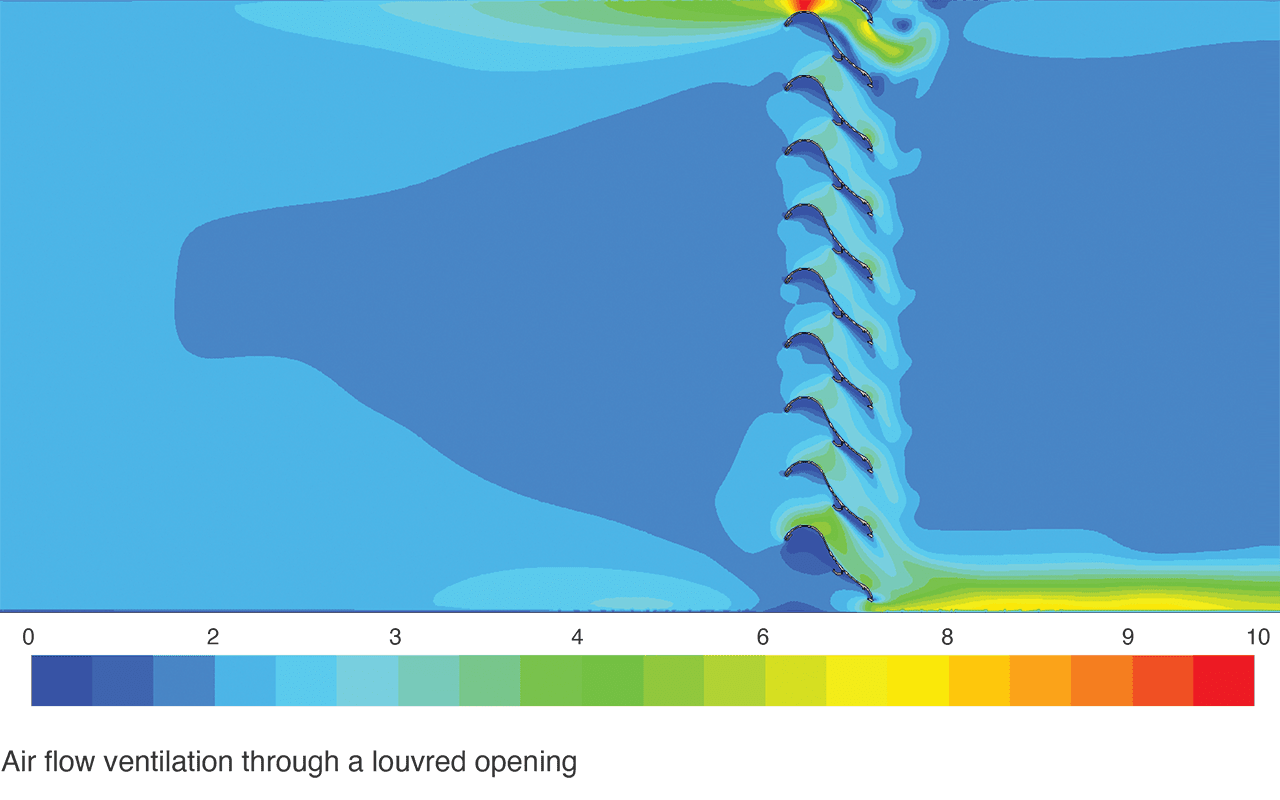

09. Replacement Air Inlet

Replacement air is essential for any smoke control system to function effectively. The velocity of incoming air should be limited to a maximum of 5m/s in buildings. A powered inlet should not be used as it will create a push-pull effect as the fire size changes, resulting to turbulence of smoke layer causing smoke logging or even seriously affecting the opening or closing of fire escape doors.

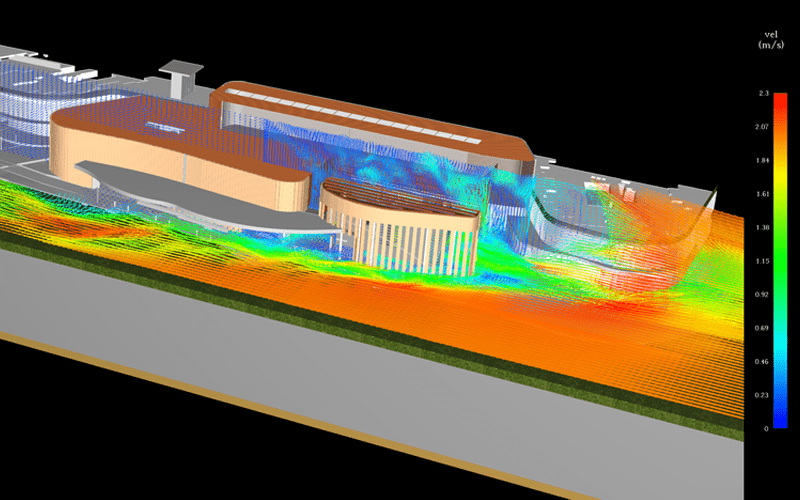

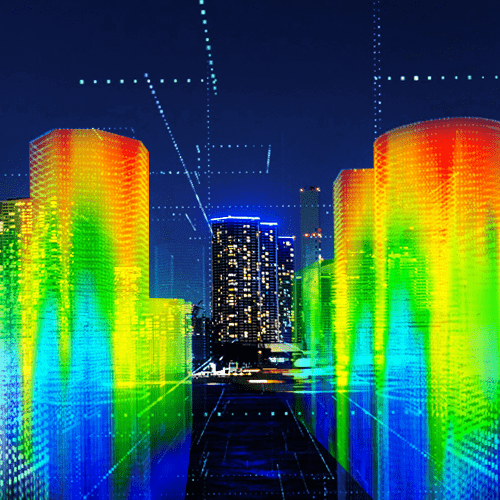

10. Wind Effects

Very often, when a window breaks in a fire compartment during a fire situation, the effects of the wind can cause unpredictable and undesirable smoke movement in the building. For example, if the window on the windward side of the building breaks, the positive wind pressure can drive the smoke backwards into the building throughout the fire floor and even to the other floors, causing smoke logging and obstruction for the occupants to escape.

Therefore, wind analysis and studies are essential to ensure that the smoke control designs are functional and reliable under the effects of wind overpressures.

In any case that the adverse wind pressures cannot be overcome, a mechanical smoke extraction system may have to be used.

Contact Us

Follow us on: